Best Way to apply floor marking tape

Floor marking tape is an important tool for industrial facilities, warehouses, and other high-traffic areas. It helps to create clear visual communication and prevent accidents by designating specific areas for various uses. However, it is not enough to simply slap down some tape on the floor and call it a day. Proper floor marking tape application is essential for ensuring that it lasts and serves its purpose. In this article, we will discuss best practices for installing industrial floor marking tape.

- Clean and Prep the Surface

The first step in applying floor marking tape is to ensure that the surface is clean and dry. Any dust, debris, or moisture on the surface can cause the tape to adhere poorly or come loose over time. It is essential to sweep or vacuum the surface thoroughly before installation. In some cases, it may be necessary to use a cleaning solution to remove any grease or oil from the surface.

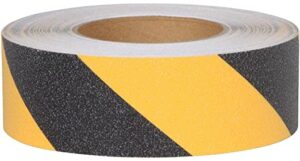

- Choose the Right Tape

Not all floor marking tape is created equal. Choosing the right tape for your application is critical for ensuring that it lasts and serves its purpose. Different types of tape have different adhesion properties, durability, and thicknesses. Make sure to choose a tape that is appropriate for the surface you will be applying it to, as well as the level of traffic it will be exposed to.

Click for buying floor marking tapes

- Measure and Plan Ahead

Before applying the tape, it is essential to measure and plan the layout ahead of time. Use a tape measure or ruler to mark out the areas where you will be applying tape. This will help to ensure that your lines are straight and evenly spaced. Additionally, planning ahead will help you to estimate how much tape you will need and avoid waste.

- Apply the Tape Carefully

When it comes time to apply the tape, it is essential to do so carefully. Take your time to ensure that the tape is straight and even. Avoid stretching or pulling the tape, as this can cause it to lose its adhesive properties. Be sure to press the tape firmly onto the surface to ensure good adhesion.

- Allow the Tape to Cure

Once the tape has been applied, it is important to allow it to cure for at least 24 hours before exposing it to heavy traffic or moisture. This will give the adhesive time to set and ensure that the tape stays in place.

Conclusion

Proper floor marking tape application is essential for ensuring that it lasts and serves its purpose. By following these best practices for installing industrial floor marking tape, you can ensure that your facility is clearly marked, safe, and organized. Remember to clean and prep the surface, choose the right tape, measure and plan ahead, apply the tape carefully, and allow it to cure before use.

More Different Types of tapes: AntiSkid, Reflective