What is Fault Tree Analysis?

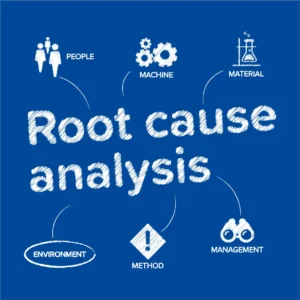

Fault Tree Analysis (FTA) is a top-down, deductive failure analysis method used to understand the causes of system failures. The analysis begins with identifying a particular undesired event (often referred to as the “top event”), and then systematically deconstructs the possible causes or failures that could lead to it. FTA uses a graphical model (a “fault tree”) to represent this causal chain, breaking down each failure into its individual components.

Think of FTA as a detective story where engineers seek to determine the root causes of a failure by working backward from the final event. This allows them to explore different failure scenarios, assess their likelihood, and identify areas where preventative measures can be implemented.

Key Components of a Fault Tree

- Top Event: The undesired outcome or system failure being investigated.

- Intermediate Events: Events that are part of the causal chain leading up to the top event.

- Basic Events: The root causes of the failure, often the simplest events or component failures that contribute to the intermediate events.

- Logic Gates: These are symbols used to connect different events. The most common are:

- AND Gate: Indicates that multiple conditions must occur together for the failure to happen.

- OR Gate: Indicates that any of several conditions can lead to the failure.

- NOT Gate: Used to negate or represent the absence of an event.

How Fault Tree Analysis Works

Fault Tree Analysis begins with the identification of the top event. From there, the analyst works backward, using logic gates to decompose the potential causes of the event. Each layer is examined in detail until the fundamental, basic events are identified.

Once the fault tree is constructed, probability values can be assigned to each basic event (if data is available). The overall probability of the top event occurring can then be calculated, helping engineers and risk managers understand the likelihood of failure and prioritize safety measures.

Applications of Fault Tree Analysis

FTA is widely used across various industries to assess and manage risks. Here are some of its most common applications:

-

Aerospace and Aviation: FTA is used to analyze potential failures in aircraft systems, from mechanical components to control systems. It helps improve the safety of aircraft by identifying weak points that may lead to accidents.

-

Nuclear Power: In nuclear power plants, safety is paramount. FTA is employed to identify possible failure modes in critical systems, ensuring that the plant remains secure and any potential risks to human life are minimized.

-

Automotive Industry: Automakers use FTA to analyze vehicle systems, such as braking or airbag mechanisms, to identify potential failures that could lead to accidents or recalls.

-

Manufacturing and Industrial Engineering: FTA helps in assessing the reliability of production systems and machinery. It’s particularly useful in environments where failure can lead to expensive downtime or safety hazards.

-

Chemical and Petrochemical Industry: FTA is employed to assess risks related to explosions, leaks, or chemical reactions that could result in significant safety hazards.

-

Healthcare: In medical device manufacturing and hospital systems, FTA is used to assess the reliability and failure modes of equipment that could impact patient safety.