Why Digitizing Pressure Gauge Readings with LeanKia Increases Reliability and Improves Maintenance Efficiency Why Digitizing Pressure Gauge Readings with LeanKia Field Data Collection Is a Game Changer In most process plants—thermal power stations, refineries, chemical units, steel mills—operators record pressure... Read more

In today’s fast-paced manufacturing world, where production efficiency, cost reduction, and equipment longevity are paramount, businesses are increasingly turning to strategies that optimize the operations of machinery and systems. One such strategy that has gained significant traction is Autonomous Maintenance... Read more

In the world of manufacturing and industrial operations, equipment reliability is crucial. Without properly maintained machinery, even the most well-planned processes can come to a halt. That’s where Autonomous Maintenance (AM) comes into play. It’s an innovative approach that involves... Read more

In the ever-evolving world of manufacturing, efficiency is key. With the increasing demand for faster production cycles, better quality products, and lower costs, companies are constantly looking for innovative methods to optimize their production processes. One such method that has... Read more

In the fast-paced world of manufacturing, optimizing production processes is critical to staying competitive and meeting customer demands. Companies are continually seeking ways to streamline operations, reduce costs, and improve product quality. One of the most effective methods to achieve... Read more

In the world of manufacturing, the ability to quickly switch between product variations or production runs is a major competitive advantage. One of the most effective techniques for reducing setup times and improving overall efficiency is SMED, which stands for... Read more

In the fast-paced world of manufacturing, one of the key factors that determine efficiency and productivity is the time it takes to switch from one product to another. This process, known as “changeover,” can significantly impact production output, especially when... Read more

Root Cause Analysis vs. Corrective Action: Understanding the Difference In any organization, problem-solving is crucial for maintaining efficiency, ensuring quality, and minimizing risk. Two terms often used in the problem-solving process are Root Cause Analysis (RCA) and Corrective Action. While... Read more

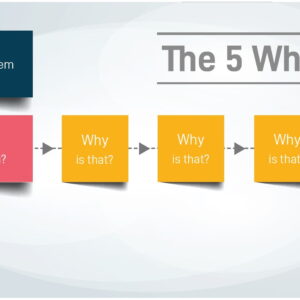

How to Conduct a 5-Why Analysis for Problem Solving Problem-solving is an essential skill in any industry, whether you’re working in manufacturing, service, or any other field. One of the most effective and simple tools for identifying the root cause... Read more

5 Common Root Cause Analysis Methods and When to Use Them In any industry, identifying the root cause of a problem is crucial for preventing it from recurring and ensuring the smooth operation of systems, processes, and teams. Root Cause... Read more