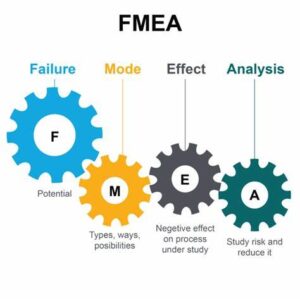

What is FMEA? Failure Mode and Effects Analysis (FMEA) is a methodology used to identify and evaluate potential failure modes within a system, product, or process. The goal is to prioritize the failure modes based on their potential impact, likelihood,... Read more

What is FMEA? Failure Mode and Effects Analysis (FMEA) is a systematic method for evaluating the potential failure modes of a product, process, or system. By identifying possible failure modes, analyzing their consequences, and assessing the risks associated with them,... Read more

In the world of engineering, reliability plays a critical role in ensuring that systems and equipment function as intended without unexpected failures. One of the key tools used to model, analyze, and improve system reliability is the Reliability Block Diagram... Read more

In the world of industrial operations, predicting when equipment will fail can make the difference between maintaining smooth operations and dealing with costly downtime. The ability to anticipate failures before they occur can save businesses significant amounts of money and... Read more

In today’s competitive industrial landscape, maximizing equipment performance while minimizing operational disruptions is critical. Companies are continuously looking for strategies to improve productivity and reduce costs. One highly effective strategy that has gained significant traction across various industries is Reliability-Centered... Read more

In the world of manufacturing, engineering, and IT systems, understanding key performance indicators (KPIs) related to system reliability is crucial. Two such important metrics are MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair). These metrics play a... Read more

In today’s rapidly evolving business landscape, organizations are constantly striving to improve their processes, boost employee morale, and maintain high levels of productivity. One effective approach to achieving these goals is through Small Group Activities (SGA). SGAs bring employees together... Read more

In today’s competitive business landscape, organizations are constantly seeking ways to improve efficiency, foster innovation, and engage employees. One of the most effective yet often overlooked methods for driving continuous improvement is Small Group Activities (SGA). SGAs empower employees to... Read more

In today’s fast-paced business environment, organizations across industries are continually seeking ways to enhance efficiency, reduce waste, and improve product or service quality. Lean and Six Sigma are two popular methodologies that help achieve these goals, but their success relies... Read more

The PDCA (Plan-Do-Check-Act) cycle is a tried-and-true methodology for continuous improvement, widely used across various industries to optimize processes, enhance efficiency, and ensure customer satisfaction. Whether in manufacturing or service industries, the PDCA cycle plays a crucial role in solving... Read more